Fox Talas 32 Oil/Seal Change Checklist

This checklist is based mainly on the Fox Racing Shox video and is meant to be used after watching the video, not as a substitute for the video. Use these directions at your own risk! Do not call me if you wreck your fork. =)

I have used this procedure on 2005 RL, 2008 RLC, and 2009 RLC Talas forks. I've corrected a couple of mistakes in the video, and have also noted some of the differences between the three forks I have.

Older Talas forks have an IFP chamber (instructions prefaced with IFP.) 2005 and 2006 forks I examined had them, while my 2008 and 2009 forks did not.

On the forks with IFP chambers, I used an inflation needle (i.e. for blowing up a football, etc) instead of a $90 (!) IFP tool. I found a needle a Harbor Freight Tools that had the same threads on the outside as a schaeder valve, so I was able to screw a shock pump onto it.

Left/right sides refer to "rider side" (i.e. position when seated on bike)

The left side is the Talas side.

The right side is the damper side.

Numbers refer to frame numbers in the Fox service video referenced above

I used a replacement seal kit from Enduro Fork Seals (Real World Cycling) which included a pair of two part seals and foam rings, an aluminum crush washer, and two plastic washers. (It looks like the newer kits may also have replacement o-rings?)

When you get to filling your fork, check Fox's Oil Volume Table This table tells you by fork model and year how much oil to put in the various parts of your fork and what type of oil. Fox states "if you discover any discrepancies between oil specifications within any of the service procedures and the information presented here, the Oil Volumes table information always takes precedence. "

I substituted 10W motorcycle fork oil for 10W Fox Suspension Fluid.

I substituted 80W gear oil for Fox Float Fluid. (Actually I used 80W90 lower outboard motor lube, but I usually read about people using gear oil.)

Again, do so at your own risk! (Fox Suspension Fluid actually doesn't cost that much more than fork oil, I just didn't have a local place to buy the Fox stuff.)

DISASSEMBLY

1. Remove fork from bike and place fork in a bike stand

2-3. Remove red rebound knob

4-5. RL/RLC - Remove the lockout lever by loosening the three set screws. These also retain ball bearings on the underside, which press against the shaft... if you loosen the set screws too much, the balls may slide past the set screws to the outside. I loosen the screws 1/2 turn at a time until the knob comes off, maybe 1-1.5 turns total. The balls are held in by grease only, be careful not to lose them.

6. RLC - Remove the low speed compression dial

7-8. RLC - Remove the ball and spring with a jeweler's screwdriver, tweezers, dental pick, etc. Be careful not to lose the ball and spring.

9-10. Remove air cap from Talas/left side.

11-12. Remove locknut with 7/16" socket - admire the locknut (as per video. =) Note: on my 2009 fork there is no locknut, instead remove the two allen screws from the travel adjust knob.

13-15. Remove travel adjust knob, then remove the ball and spring underneath. Note: 2009 fork did not have a ball and spring.

16-21. IFP - remove the red screw, then insert inflation needle and release pressure (put rag over needle, as some float fluid may spray out.)

22-24. IFP - release air from the Talas main air chamber's schraeder valve. Then release more air from the IFP port with the needle. When both chambers are deflated, remove the needle

OR

16-24: No IFP: Release all air from the Talas main air chamber's schrader value

25-26. With 26mm socket, loosen the right side topcap until you can just see the o-ring.

27-28. Turn fork upsidedown, remove right side knob on bottom of fork (blowoff threshold knob.) Use 2mm allen wrench, and only unscrew set screw far enough to remove knob. (Note: My 2005 RL doesn't have this knob.)

29-30. With 10mm socket, remove nut and plastic washer from bottom of right fork leg.

31-33. Remove nut and aluminum crush washer from bottom of Talas/left fork leg.

34-36. Thread the nut from the right fork leg back on to the right stud so it is flush with the adjuster rod (to prevent damage to the rod.) Tap the nut with a plastic hammer (or a wood block and hammer), a whack or two until the rod drops. Remove the nut, and push the stud into the lower, then turn the fork right-side up over an oil pan so it can drain. Pump the lowers up and down slowly to expell oil, if stud drops through lower, push it back up again to open drain hole.

37. Remove the lowers

38-40. Unscrew right topcap and pull damper assembly out. Release fluid from damper assembly by pressing check valve with 1.5mm allen key. Pump assembly with check valve open to remove all the fluid. The damper has an o-ring near the top of the lower slider. If you knock it out of position while pumping the oil out, be sure to put it back. (Note: you can do a lot of the pumping with the check valve open while the damper is still installed in the fork, then remove it to get the last bits of fluid out... it's a little less messy that way.)

41-44. Unscrew left/Talas topcap and pull out. Clean the Talas upper shaft with a lint free rag.

45-48. Remove the Talas lower shaft by pushing up on the stud, then using an 8mm allen wrench to push it to the top of the lower. Pull the lower shaft the rest of the way out and clean with lint free rag. The Talus lower shaft has an o-ring set into the bottom near the stud. Sometimes it falls out - make sure to put it back and not lose it!

Extra, from F100 instructions

- Remove the rubber bumper from each side of the lowers with a hook (I made one from a plastic coated coat hanger.) Be careful not to scratch the inside of the fork.

- Clean the dirt/mud/sand out of the inside of the lowers with a bottle brush, water, and a small amount of Simple Green in the sink.

- Rinse with a lot of water

- Hang upsidedown to dry, or dry with a hair dryer (as per Fox instructions.) Make sure all the moisture is out before you reassemble the fork.

REASSEMBLY

49-52. Pour 3ccs of Float Fluid into the left upper tube, with the fork on an angle so it doesn't run out, then insert the Talas lower shaft assembly. Push the lower shaft down with a 1/2" piece of PVC tubing until it extends below the upper by about 2-3 fingers.

53. Pour 5ccs of Float Fluid into the left upper tube, on top of the lower shaft assembly.

54. Insert the Talas upper assembly, making sure to line up the rod with the hole in the lower shaft.

55. Pour 3ccs of Float Fluid into the upper tube. (Note: the video shows the Float Fluid being poured between the bottom of the silver piece and a rubber stopperish piece - not all year forks have this stopperish piece.)

56-58. Push the Talas upper assembly all the way down and tighten the topcap with a 26mm socket to 165 in-lbs (roughly 13.7 ft-lbs)

59-62. IFP - Insert inflation needle into IFP port and inflate to 150psi w/ shock pump. (Note: This may require two people, although I was able to do it by myself.) Remove needle and reinstall red screw. Make it snug, not overtight.

63-65. Reinstall spring and ball, push ball into detent with dental pick, small screwdriver, etc

66-69. Grease bottom of Talus travel knob, then reinstall. Reinstall lock nut. with 7/16" socket. Note: Fox video specifies a torque of 45 in-lbs. This is TOO TIGHT and will strip threads. I made the locknut "snug" at about 20 in-lbs...(?) I read one suggestion that said if you strip the threads, use a washer to move the nut up to good remaining threads.

OR

Note: for steps 63-69, 2009 fork has different travel knob which has no ball/spring underneath and is held in place by two allen screws rather than a locknut.

71-72. Inflate main air chamber to 75 psi and reinstall air cap on schraeder valve.

73-75. If replacing the seals, remove seals with an open end wrench, then remove the foam rings. Be careful not to scratch the inside of the fork.

76-77. Slide new seals, then foam rings onto the upper tubes. Dip the foam rings in suspension fluid before installation. (Note: Enduro Fork Seal's seals are two pieces plus a foam ring. The lower piece has a ring with a split and spring on one side. I put that side down towards the foam ring, but I'm not sure if that is correct -?)

Extra: If you removed the bumpers from the bottom of the lowers, reinstall them now!

78-79. Slide the lowers onto the uppers (make sure the orientation is correct, arch is the front on my forks.) Use blunt object (i.e. end of 8mm allen wrench) to insert/seat the seals into the lowers.

80. Turn for upsidedown and pour 10cc of suspension fluid into Talas side.

81. Push lower down so Talas stud comes up through lowers (may need to guide stud through)

82-83. On the Talas side, install aluminum crush washer, then nut. Tighten nut to 50 in-lbs.

84. Insert damper assembly into the right side and tighten the topcap a couple of turns.

85-89. Guide the base stud through the lower, install a plastic crush washer, then the nut. Tighten nut to 50 in-lbs.

90-91. Reinstall blue blowoff threshold knob with 2mm allen wrench.

92. Turn fork right-side-up, reopen the right topcap and pour in 160ccs of suspension fluid into the upper. (Note: check volume table and make sure this is the correct damper volume for your fork.)

93. Reinstall right topcap and torque to 165 in-lbs with 26mm socket.

94-95. Reinstall spring and ball. Push ball down gently with tool.

96-97: RLC - grease low speed compression knob bottom, then reinstall. Line up any one of the divots in the knob bottom with the ball and spring.

98-99: RL/RLC - Resinstall lockout lever. Keep turning cw, taking knob off and reorienting, etc until knob won't turn anymore. Take knob off and reinstall with lever in the 6 o-clock position (i.e. back of crown, towards rider.) This is locked. (Note: Fox video says 12 o-clock and unlocked... I think there's a mistake there.)

100: RL/RLC - Lightly tighten the lockout lever set screws, then back them off 1/4 turn (Note: Fox video says 1/2 turn, but I found the knob had some play when I did that, YMMV.) Rotate lockout lever to the unlocked position.

101-102: Reinstall the red rebound adjuster knob and screw.

103: Cycle the fork a few times. (Note: you may at this point want to return the controls to where you had them set, reinflate the Talas side to the proper pressure for your weight, etc.)

If you enjoyed this article, please consider buying my products ...

|

|

|

ATX PS Adapter

Use an ATX PC power supply as a 5V, 3.3V, and +12V/-12V bench supply the easy way, without cutting the case or mounting external connectors, resistors, LEDs, switches, and fuses. Provides visual indication when supply is plugged in and turned on, also fuses the power voltage outputs for safety. Run USB powered development boards via the USB connectors on the 5V line. |

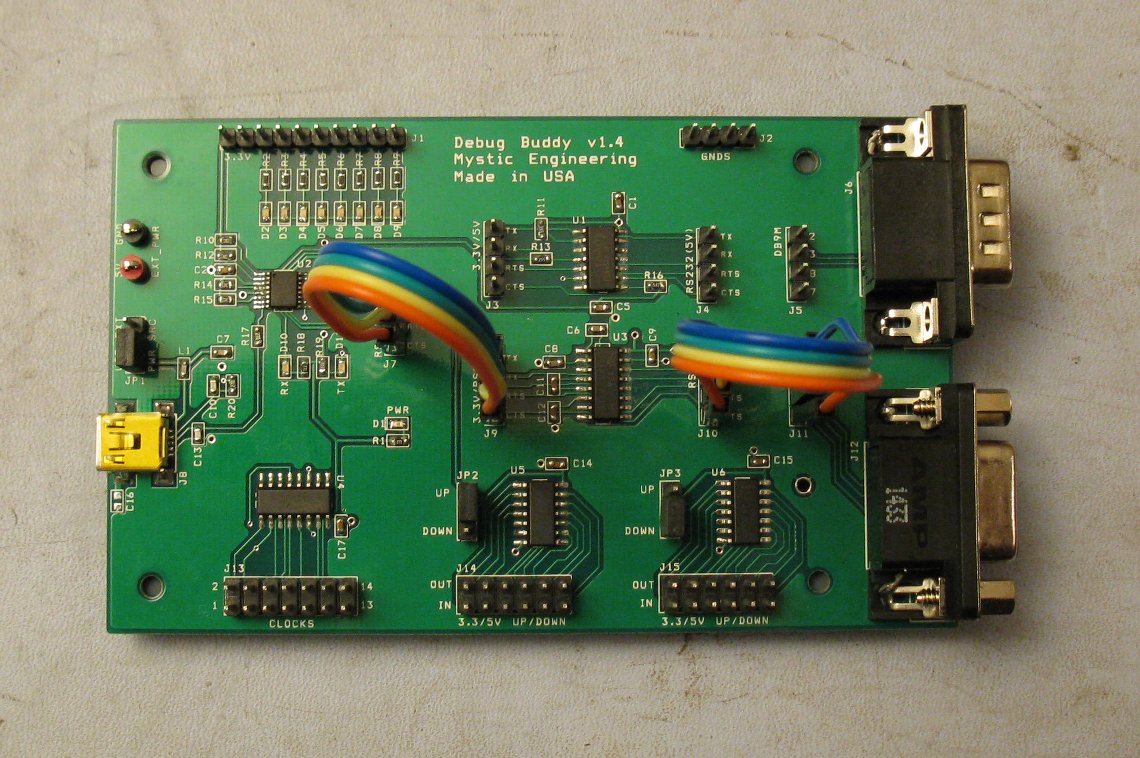

Ultimate Serial Port (Debug Buddy)

USB serial port with standard, 5V and 3V RS232, plus integrated null modem and gender changer. Implements TX/RX and RTS#/CTS# for optional hardware handshake. Also includes 3.3V<->5V level shifters, debug LEDs, and 13 clock sources. Valuable tool for hands on problem solving and hacking |